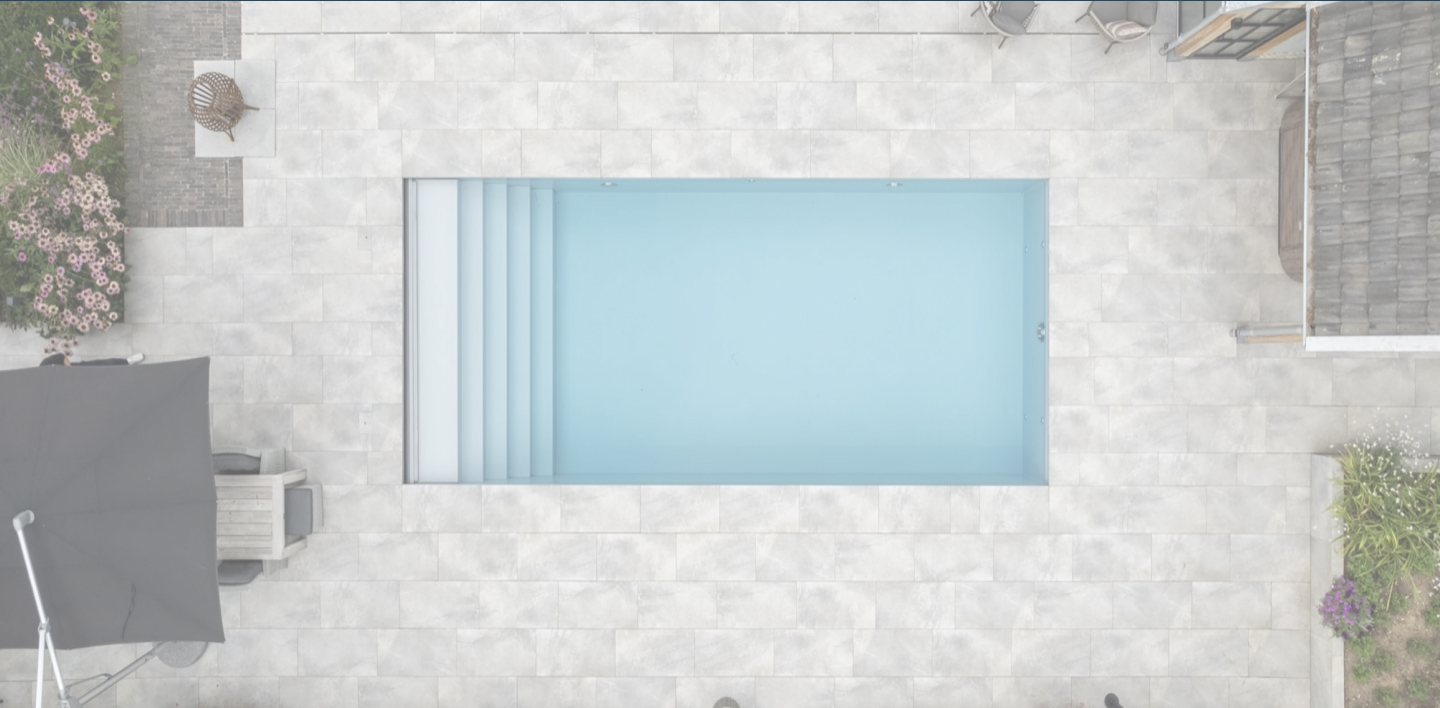

The original Monoblock® swimming pool

Starline Monoblock®

Protecting a product name is no mean feat. Starline is the first and only manufacturer in the Benelux of fibre-reinforced swimming pools. But the Monoblock® is more than just a pool. It is a unique and trusted method we have been using for 50 years. Discover the unique characteristics of the original Monoblock® pool compared to a monoblock or monopole pool.

To start with

What is a Monoblock® swimming pool?

A Monoblock® is a high-quality fibre-reinforced pool in one piece with pre-assembled pipework and built-in parts. It is like a ready-made pool that is installed directly in the ground. This not only eliminates the risk of mistakes during placement and installation, but makes them last longer than traditional pools. At Starline, you have a wide choice of styles, sizes, walk-in steps, colours and options.

Monoblock® vs concrete pool

What makes our Monoblock® so unique?

With concrete pools, all the work is done on site, such as making a concrete tub and applying foil, mosaic or tiles. Processes that are not only time-consuming and energy-intensive, but also prone to errors. With a Monoblock® pool, you do not have to deal with this and experience less inconvenience due to construction work. Moreover, the shell is seamless, making it less sensitive to leaks and wear, resulting in a longer lifespan.

- 001

The sturdiest construction with optimal insulation

A Starline pool weighs between 1000 and 3000 kg. This is because we do not compromise on the use of vinylester and insulation material. Our double-walled construction consists of seven different layers, carefully applied layer by layer by our craftsmen.

- 002

A solid and seamless construction

A Monoblock® pool is made in one piece, shaped by a production mould and then cured in the oven. This makes the pool seamless and leakproof. The walls and bottom therefore have the greatest degree of flatness, straightness and smoothness.

- 003

Sleek walls of unrivalled quality

We are the only manufacturer to offer composite pools with sleek walls, i.e. where the walls are almost perfectly straight. The 91° radius between the bottom and the walls not only affects the visual aspect, but also highlights our expertise in the production process.

- 004

Quality over quantity

To guarantee our quality standards, we choose to produce our pools to order and locally. Storing pools, stacked, outside is a no-go for us. Therefore, we consciously choose to transport our pools directly from the factory to site.

Your guarantee for years of swimming pleasure

Our trusted method

The Starline Monoblock® stands out because it is manufactured to order and locally in Belgium. Once ready, the pool is transported directly from the factory to the desired location. The authorised Starline Dealer carries out all the necessary work in the garden and arranges the installation and connection from A to Z. We have been using this unique and reliable method for 50 years, which is your guarantee of years of swimming pleasure.

Material and Construction

Layer by layer, with great care

The walls and bottom of a Monoblock® pool consist of seven different layers, carefully applied one by one by our craftsmen. For optimal insulation of the pool, a honeycomb premium skincore (honeycomb structure) is used in the bottom, and a high density isolation foam is incorporated into the walls.

The dual-crosslayer fullforce vinylester layer makes the whole structure impermeable to water. That’s why we offer a lifetime warranty on the water-tightness of the Monoblock®. The gelcoat ISO-NPG layer determines the color of the pool and is extremely suitable for pools due to its high UV resistance. All these materials together ensure exceptional strength and high insulation value.

“With careful handwork, layer after layer, our team realises the dreams of many customers every day. That is something we are proud of and that should be seen.”

Michel Bosscher - Production Manager Starline

Visit our swimming pool factory

Wondering how your swimming pool is made? We welcome you for a tour of our state-of-the -art production facility in Pelt (Belgium)!